An Industrial Guide to Protecting Metal and Steel Surfaces

The key to successful application of any high-performance paint system is preparation, and rust-inhibiting metal primers are integral to many maintenance and repair systems across the industrial building, renovation, and commercial property sector. Applying paint directly to unprepared areas can mean that the paint topcoat has nothing to successfully adhere to – and the whole paint system which is being installed will need to be completely stripped back (often at great expense) and reapplied to a newly prepared surface. Avoid the additional costs, potential business downtime and loss of earnings, and headache by making sure all metal surfaces that are to be painted have been correctly prepared and primed. You will save time and money this way, and more importantly, get the full lifespan of the product – colour protection, UV resistance, weather and waterproofing, and enhanced brand/company reputation! Click here to skip recommended products and to continue reading.

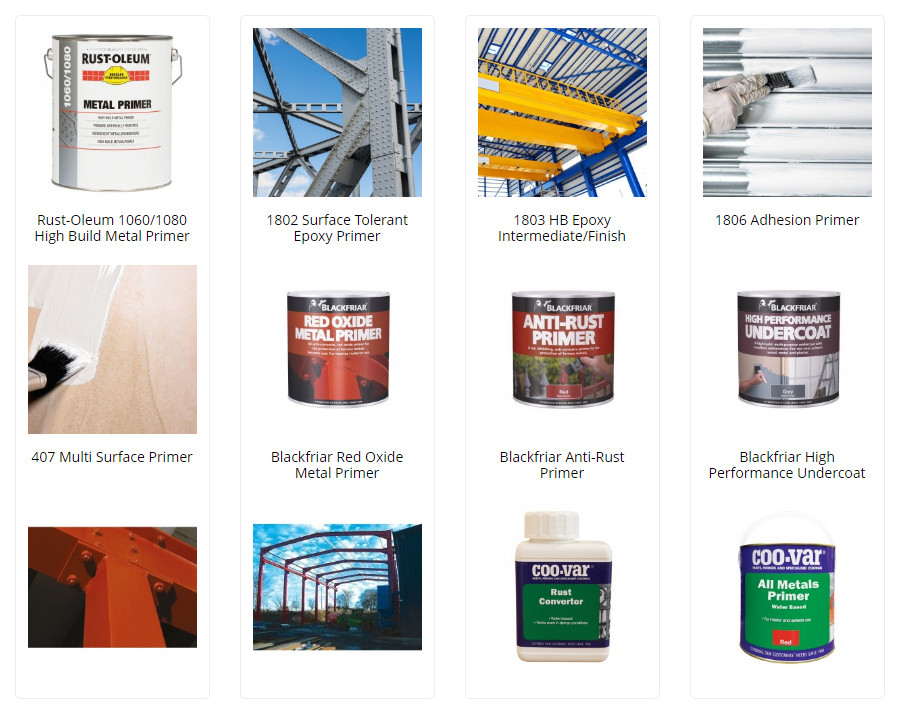

Get 10% Off These Featured Products

Voucher code will appear on product page

Viewing this on mobile? Already know which products you want? Shop here.

- How Do Steel and Metal Primers Work?

- What Surfaces Can Metal Primers Be Used On?

- Surface Requirements and Product Recommendations

- Rust-Converter Products

- New, Bare Steel, Blasted Steel or Galvanized Steel Surfaces

- Tintable Stainless Steel, Carbon Steel, Galvanising, Aluminium, Copper and Brass Primers

- Hand Prepared and Blast Cleaned Steel

- Red Oxide Metal Primers for Ferrous Metals

- Special Primers for Coastal and Extreme Exposure Conditions

- Temporary Metal Protection

- Industrial Location Metal Primers

- Primers for New Construction

- Rust-Inhibiting and Anti-Corrosive Metal Primers

- More Information

How Do Steel and Metal Primers Work?

First and foremost, a primer (sometimes incorrectly referred to as ‘undercoat’) is the key element of a surface, substrate or material’s preparation before it is painted with a topcoat. Once a surface has been cleaned and all loose materials – dirt, grease, grime, mould, algae, most, rust, etc. – removed, a primer should be applied for better adherence of the paint to the surface.

Previously coated surfaces may not require a primer, but new, bare, raw, exposed and porous materials should require a primer to seal, bond and add extra protection to the full paint installation. Using the right primer and topcoat will produce an elevated level of durability, full aesthetical values – colour and sheen retention – and last for years to come.

Paints’ adhesion to metal surfaces is lower than its adhesion to porous substrates, such as wood or masonry, and in certain instances paint can form very little adhesion with the metal surface as it dries and cures. A primer will stop this happening by forming a binding layer and allowing for a smooth, level and even paint topcoat application – as well as improved coverage ratios. Many untreated or exposed metal surfaces have a sheen, shine or gloss to them – which can make it impossible for standard paint to adhere to. Steel, or more specifically, stainless steel, will not allow paint to adhere to it. A primer will create the bond between it and the paint.

Primers are frequently picked based on their rust-inhibiting qualities for environmentally demanding environments – structural steel, oil-rigs, marine equipment, etc.

With a wide range of metal paints, colours and finishes available at Rawlins Paints, including enamel paint, hammered finishes and aerosol applied coatings, get the best suited metal primer for the topcoat by referring to product datasheets or contacting our technical support team.

Metal primers and undercoats to tackle rust are available to buy today at Rawlins – click the image to view all

Please ensure that metal topcoats are applied when specified by the primer. By not applying a compatible topcoat within the recommended time frame, it can severely reduce the performance of the system. In certain instances it may be possible to apply the topcoat before the primer has fully cured, to improve adhesion and inter-coat adhesion on difficult surfaces.

When applying a coloured topcoat, it is recommended to apply a similarly tinted undercoat/primer, to improve colour performance and reduce the number of topcoat layers to achieve the desired colour and aesthetical finish.

What Surfaces Can Metal Primers Be Used On?

Metal primers available to buy today at Rawlins Paints, can be used on metal and Plastisol cladding, aluminium, copper, iron, lead, mild steel, cast iron, galvanised steel, stainless steel, zinc and more. For other requirements, please contact us for further product recommendations.

The products available to buy here, can be used on:

- Bridges

- Tower blocks

- Mining equipment

- Power plants

- Breweries

- Marine vessels

- Power plants

- Petrochemical plants

- Offshore refineries

- Canteens, restaurants and large food preparation surfaces

- Lift doors

- Shutter doors

- Industrial processing and manufacturing equipment

- Tools

- Vehicles – cars, motorbikes, tractors, forklift trucks, pallet trucks, lorries, etc.

- Fencing, barriers, gates, posts, etc.

- Cranes, cherry pickers and other heavy-duty lifting equipment

- Pipes, sewage and drainage systems, and guttering

Many of our primers and undercoats have impressive certificates and approvals including hygiene ratings, fire ratings, Network Rail approval, Highways Agency approval, London Underground approval and more. Ask our Technical Team for help in choosing the right primer or undercoat for your project.

Surface Requirements and Product Recommendations

Rust-Converter Products

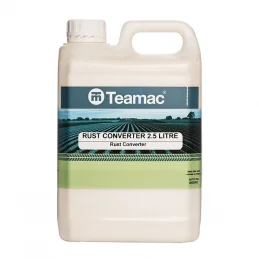

For areas where rust cannot be fully removed, such as on steel or iron surfaces, Teamac or Coo-Var’s Rust Converter can be directly applied to the rust to protect and prevent it from spreading further. Essentially, a rust-converter will turn the rust on a substrate into a stable surface that can be re-coated without any risk of further corrosion to the underlying metal.

New, Bare Steel, Blasted Steel or Galvanized Steel Surfaces

For damaged galvanised steel, or light industrial exposure, corrosive environments and high humidity areas, Rust-Oleum Hard Hat Galva Zinc Alu will act as a fast drying and zinc enriched primer. Providing excellent cathodic protection with its pure zinc and aluminium pigments, it dries to leave a sparkling aluminium finish. This product essentially acts as a compromise between substrate protection and an aesthetically sound finish, which is heat resistant up to 100°C.

Tintable Stainless Steel, Carbon Steel, Galvanising, Aluminium, Copper and Brass Primers

To reduce the number of topcoat layers to achieve a brand specific, or unique colour finish, Rust-Oleum 3202 Galvinoleum Primer is tintable to nearly any colour, including RAL and British Standard colour finishes. It is a single pack super adhesion primer for galvanised steel, plastic or other smooth surfaces. Should be used on galvanised steel, stainless steel, aluminium, copper, glass, porcelain and other smooth, dense surfaces.

Hand Prepared and Blast Cleaned Steel

Rust-Oleum 769/780 Damp-Proof Rust Primer is a single pack rust primer for direct application on slightly moist or dry metal surfaces. Rust-Oleum 769/780 Damp-Proof Rust Primer is specially developed to be applied on hand tool prepared sound rusted steel surfaces. Can be applied on slightly damp surfaces and is providing protection under light industrial exposure conditions, if followed by a second primer Rust-Oleum 1060/1080 High Build metal primer and/or Rust-Oleum 7500 Alkythane.

Red Oxide Metal Primers for Ferrous Metals

Red oxide primers deliver excellent water-resistance for steel and iron structures. They are ideally suited for ferrous metals, protecting it against rust and corrosion. Teamac, Blackfriar and Coo-Var each manufacture red oxide metal primers, available to buy today at Rawlins Paints.

Ferrous metals typically contain iron, and are magnetic – offering minimal corrosion resistance. Ferrous metals include mild steel, carbon steel, stainless steel, cast iron, and wrought iron. Non-ferrous metals are not magnetic, nor contain iron – these are more resistant to corrosion than ferrous metals.

Ferrous metals, for which red oxide metal primers can be used on, can be found in huge architectural metal structures – bridges, skyscrapers and tower-blocks.

Special Primers for Coastal and Extreme Exposure Conditions

Exterior iron, steel and aluminium structures in coastal areas will require a surface primer with excellent anti-corrosive properties, and for this, Coo-Var’s Zinc Phosphate Primer is a suitable product. Generally sold in smaller sized tins, it is commonly used on fire escapes, metal gates and garage doors.

Teamac manufacture three excellent zinc phosphate primers – Teamac QD Zinc Phosphate Metal Primer, Teamac 2 Pack Zinc Phosphate Primer and Teamac Rapidry HB Zinc Phosphate Primer.

Temporary Metal Protection

Rust-Oleum 6400 Fast Drying Shopprimer is suitable as a solvent based, temporary metal protection, commonly used as the first coat in shop coating applications. It provides basic protection following metal fabrication and assembly operations. Click here for the water-based 6400WB.

Industrial Location Metal Primers

For offshore environments, refineries, power plants, bridges, buildings, mining equipment and general structural steel, Jotun offer an excellent range of metal primers, including Jotun Barrier 77. Jotun’s paints and primers are manufactured to deliver unparalleled protection in the most demanding and atmospheric working and building environments around the world.

Jotun Barrier has pre-qualification testing in accordance with NORSOK M-501, Rev. 5, System 1, and is suitable for exterior exposure in offshore environment, below 120 °C. It is part of a complete system that is certified to Network Rail Line Specification NR/L3/CIV/039 – System M20 and N4 (Cert. No. XM92/M20-140 and XN90/N4-077) Item 7.1.3.

SikaCor EG 1 Rapid is a two-pack, high-solids, epoxy-based intermediate coat containing micaceous iron oxide. It is designed as a mechanically resistant intermediate coat on steel surfaces exposed to atmospheric conditions, hot-dip galvanized steel, zinc-spray, stainless steel and aluminium. It is over-coatable at low temperatures till – 10°C and is usually insensitive against shock and impact.

International Intercure 384 is an industrial metal primer which acts as a high build intermediate to provide excellent barrier protection as part of a high-performance system in aggressive environments including offshore structures, bridges, chemical and petrochemical plants and power stations. It is pigmented with micaceous iron oxide to comply with the requirements of BS5493:1977

International Intercure 200 is a primer for industrial scale steelwork and intended for use in a wide range of aggressive environments, including offshore, chemical and petrochemical plants, industrial buildings, pulp and paper mills, power plants and bridges.

For marine primers, International Interlac 497 is a one pack alkyd undercoat for use on internal and external areas above water on marine vessels.

International Interplate 937 is a two pack, heat resistant zinc silicate shop (pre-construction) primer, suitable for high speed welding and cutting, with excellent resistance to damage caused by welding, gas cutting and fairing.

Primers for New Construction

Another Jotun product, Penguard Primer, is a two-component polyamide cured high molecular weight epoxy coating designed as a primer for new construction structural steel and piping. For use on offshore environments and similar locations to Jotun Barrier, it is designed to be part of a complete system in atmospheric and immersed industrial environments, it is suitable for properly prepared carbon steel, stainless steel, aluminium, concrete, galvanised steel, shop primed steel and thermally sprayed zinc substrates.

Jotun Penguard Tie Coat 100 has pre-qualification testing in accordance with NORSOK M-501, Rev. 5, System 1, suitable for exterior exposure in offshore environment, below 120°C.

Rust-Inhibiting and Anti-Corrosive Metal Primers

When looking for a rust-inhibiting metal primer, please check that the product states clearly that it offers this. Rust-Oleum metal primers are typically rust-inhibiting. To prevent oxidisation and rust, ‘sacrificial’ zinc is added to a primer, which oxidises itself, instead of the underlying metal surface. It takes years for the breakdown of the zinc additives, and until then, the metal surface will not oxidise itself.

Rawlins Paints have a vast range of rust inhibiting primers and undercoats for all ferrous and non-ferrous metals – because it is important to choose the right one for your project, whether you’re looking for something to adhere to a difficult surface, prevent rust from forming, stabilise existing rust or a high-performance system that is going to stand the test of time we have a product suitable.

For areas exposed to high humidity, standing water, steam, condensation, or rigorous cleaning schedules, metal surfaces which may have been sufficiently primed a long time ago, may need stripping back and priming again to remove any rust build up, surface and topcoat degradation, such as blistering, peeling or paint splitting, or colours that are fading with overtones of a brown rust infusion.

Steel, one of the most common materials primers are used on, is a ferrous metal. If exposed to moisture and oxygen, it can begin to rust quickly and spread rapidly. If rust and surface discolouration has begun, cleaning and stripping the rust spots back with a wire brush is recommended. Additional primer coats may be required, dependant on environmental exposure levels and how much rust-inhibitance is required.

Without using a primer, oxidation may quickly lead to rust and breakdown the stability, leading to the decay of, metal. Topcoats can peel, blister, split and lose all waterproofing protection. If you are in doubt about the protection qualities of a metal topcoat or direct-to-metal paint which states it does not always require an undercoat or primer, please contact us. Stainless steel does contain properties that can protect the surface against oxidisation – but added protection and improved adherence for the topcoat may be recommended.

Aside from rust, metal surfaces, namely aluminium, can suffer from surface chalking. Externally facing aluminium can be found on sidings of outbuildings and offices on building sites – portaloos and Portikabins, for example. As aluminium siding can dent easily, a flexible primer and topcoat will act to reinforce rust-inhibiting protection.

More Information

Rawlins Paints are the UK’s leading industrial paint specialist company, and the range of metal primers and undercoats we distribute for the industry’s leading manufacturers – International, Jotun, Mathys, Rust-Oleum, Sherwin Williams, Sika and Teamac is second to none. Our technical support team are experts on all products across each manufacturer’s range, so if you require more specific product information, a large project quote, or recommendations on compatible metal topcoats, please contact us by phone, email, or leave a comment below.

Rawlins Paints Blog Industrial Paint Tips, Guidelines & DIY Articles

Rawlins Paints Blog Industrial Paint Tips, Guidelines & DIY Articles

Hello,

I was wondering if you could help…

Can I use a zinc-alu spray then a primer then a colour top coat?

It’s bare steel stripped back completely.

Thanks for your time.

Hi Richard,

We would normally recommend the Zinc Alu Spray be left as a finish, if you are looking for a painted finish we would recommend a high build anti-corrosive primer be applied directly to the prepared steel followed by 2 coats of an anti-corrosive topcoat – the products we would recommend for this would be as follows:

Rust-Oleum 3369/3380 CombiPrimer Anti-Corrosion

Rust-Oleum CombiColor Original

Hope that helps – our technical support team are available on 0113 2455450 (option 2) or send a message to [email protected] should you need any further information – or simply come back to us here.

What would you recommend for a primer for tin cans? I paint them using acrylic paint for arts and crafts purposes but they are rusting over time.

Thanks

Hello Anna,

For tin, we would recommend Zinsser Bulls Eye 1-2-3 as a primer.

Certainly let us know if we can be of any further help.

Hello!! Hope you are doing well, I’ve a question regarding steel plates and jigs of ships so which type of Blasting we should apply and also standard and second which type of primer and its coat should apply after blasting, also mention DFT if it is required ?

Hi Muhummad,

Doing well, thank you for asking! Assuming the steel plates are areas of a floor we would recommend the following primer and anti-slip system – the required preparation can be found in the data sheet for the primer on the product page:

If the system is not for floors and doesn’t need to be anti-slip we’d go with the same primer followed by an alternative topcoat as follows:

If you need any further help then please feel free to contact us here through the blog or our technical support team directly on 0113 2455450 (option 2) or send a message to [email protected].

Does Red Oxide primer need a top coat to be most effective? Or will it have the same rust inhibiting value by itself on mild steel outdoors?

Thanks

Hi Jacob,

Primers should be protected with a compatible protective topcoat; primers are not resistant to weathering, so will break down and the steel underneath will then start rusting. A product like Rust-Oleum CombiColor would be a great choice of topcoat as this also contains corrosion protection properties for layer of protection.

If you have a particular project in mind, feel free to contact our technical support team directly with your requirements on 0113 2455450 (option 2) or send a message to [email protected].

Hi I’m looking to cure spots of rush and blistering of paint on the bodywork and sils of my transit van. I guess an inhibitor is needed prior to spray or paint undercoat. Can you please advise best products to use.

Hi Graham,

Although not really designed for automotive application we would recommend the following system for application on to a sound rusted surface:

Hi, I am refurbishing some galvanized pool panels, and after some research its not clear as to the best way to finish the panels. The panels have a lot of white rust and some areas have rust with pitting. I washed off the white rust, and sanded off the loose rust. I was going to apply a rust converter ( to get into the pitted parts) and then lightly sand and apply a high zinc paint (rustoleum cold galvanizing compound). Significant ares of the panel will still have the original galvanized finished (but lightly sanded). Is this ok, or just use a rust paint (not galvanized)? A pool liner will cover the painted surface.

Regards and thanks in advance

Hi Chris,

Sorry for the delay in answering, we’ve had a look into this and can offer the following advice:

Remove any existing rust and clean down the galvanised sections with Teamac Mordant Solution, and apply a coat of Teamac Metaclor Antifouling Primer followed by 2 coats of Teamac Chlorvar Chlorinated Rubber.

I’ve put links to the products on our online store so that you can read more about them, and certainly come back to us if you need any further information.

We have a 150 x 150 x 6 SHS that is in a semi exposed location om the soffit of a terrace and it primed with red oxide but should have been hot dip galvanized. Is there a coating that can be site applied that will comply with a C3 exposure location. Any advice would be welcomed.

Hi Leslie,

We would recommend Rust-Oleum 7500 Alkythane for this application, which is suitable up to a C4 environment. Hope that helps, feel free to come back to us if you need any further help.

What primer and top coat would you recommend for new HSS steel used in an outdoor patio cover. It would be great if the top coat could be color matched to the house ( bone ). The cover will also have Aluminum components which I’d like to also match the house.

Hi Lance,

There would be 2 primers required in this situation, one for the mild steel and another for the aluminium – for mild steel we would recommend Rust-Oleum 3369/3380 CombiPrimer Anti-Corrosion and for the aluminium we’d recommend Rust-Oleum 3302 CombiPrimer Adhesion. Both primers would then be overcoated with Rust-Oleum CombiColor Original which is available in RAL and BS colours in either a Satin or Gloss finish.

Hi,

I was wondering what you paint system you would recommend to apply to copper so we can eventually build up to putting gold leaf on it. It’s a coastal area with salt spray etc. I suppose another factor is expansion and contraction of the copper!

Would really appreciate if you could let me know,

Best wishes,

Leon

Hi Leon,

As a direct to copper primer/finish we would recommend Bradite One Can. The copper should be cleaned, degreased and preferably lightly abraded if possible.

Hope that helps – let me know if you need anything else.

Hi,

I am installing a steel exercise pool half-in the ground and half above-ground, in a concrete wall surround that should keep the outside of the pool walls dry. However, because occasional splashes or other water ingress means the bottom few inches of the pool walls may sit in water for a short time until it drains. For this reason, the manufacturer states “ideally, the bottom 6″ of the walls are treated with a rust-inhibiting primer…”. What primer do you recommend?

Hi Andrew,

Thank you for getting in touch. Assuming the steels wouldn’t be exposed to UV/Sunlight then we would recommend using Jotun Jotamastic 87.

Usually a coat of Jotun Jotamastic 87 Alu would be applied at 200microns DFT followed by a coat of Jotun Jotamastic 87 in a standard colour at 150microns DFT.

If they do become exposed to sunlight then it can cause discolouration of the coating, however this wouldn’t be detrimental to the performance.

I hope that helps, please feel free to get in touch if you have any further questions.

Many thanks

Stuart

Hi,

I’m trying to paint bright white an old rusted anchor and was wondering if you could advise on a course of action, is the Teamac rust converter needed and if so as what point in the process? Should I use a primer/sealer? If so, as its already white will I need to paint an additional layer of paint over it?

Can you recommend some kind of finish for the last layer to seal the whole thing off?

Many thanks

Leo

Hi Leo,

Many thanks for the question. Please could you let us know if the anchor is for show/display and therefore is no longer being submerged or if it is still in use and therefore submerged?

Once we have this info we will be happy to help and advise.

Please let me know if you have any further questions.

Many thanks

Stuart

Hi ,I am about to paint my backhoe some spots of deep pitted rust and some surface ,the majority of machine has decent paint . I really do not want to strip the whole thing to bare metal.so far I have degreased it and pressure washed all of the oil and loose rust and much of a. Previous paint someone else applied my plan was to wire wheel or sandblast only the rusted spots then prime them ,and fill the pits with body filler.should the whole machine be sanded then primed or can I top coat the whole thing or should it all be primed then do I have to sand the primer before I apply the top coat wondering if you can guide me thru the best process from start to finish and the products to use thanks

Hi Darren,

Thank you very much for getting in touch.

If you are looking to paint the bodywork only then yes, mechanically prepare any rusted areas and remove any loose flaking paint from other areas.

Any bare areas should be primed with an anti-corrosive primer such as Rust-Oleum 3369 CombiPrimer Anti-Corrosion and any existing paint will need to be be abraded to create a key, followed by 2 coats of Rust-Oleum CombiColor.

If it is the bucket itself that requires painting we wouldn’t be able to assist unfortunately, without the full bucket being blast prepared and then a suitable epoxy system being applied.

Please feel free to get in touch if you have any further questions.

Many thanks and I hope that helps.

Stuart

Hi there,

I’m wondering if you could give me any advice for restoring an old Margaud De Charf French wrought iron Safe – very similar to this one: https://www.leewrightantiques.co.uk/artworks/4847-mid-19th-century-large-french-wrought-iron-safe/ – but mine is currently painted. I don’t have much experience with this kind of work and not sure where to start.

Hi Michael,

Thank you very much for your question. Assuming you would like to keep the safe as a painted finish, we would recommend Rust-Oleum CombiColor Original be used for this application. Any loose flaking paint will need to be removed back to a sound edge, ensuring the surface is clean prior to applying 2 coats of Rustoleum CombiColor.

Please feel free to get in touch if you have any further questions.

Many thanks and I hope this helps

Stuart

Hi,

I am about to paint my rusty zinc roofing, the rust is small, it has just starting the rusting. please, which primer is best for me to choose.

Hi Yusuf,

Thank you for your question. Assuming the roof is pitched then we would recommend the rusty areas be abraded back to a sound substrate before applying Rust-Oleum Mathys Noxyde Pegarust.

Many thanks and I hope this helps

Stuart

Which red oxide paint should I use to prime an old cast iron soil pipe that is a little corroded at joints? The pipe has received several coats of paint over time.

Can red oxide primer be painted over Zinsser Bullseye 1-2-3?

What black topcoat paint would you recommend? I have used Hammerite paint on gates but I found it tricky to use and am reluctant to use it again.

Hi Peter,

Thank you very much for getting in touch.

For the cast iron downpipe (assuming it is the outside faces of the pipe) we would recommend the areas of rust be rubbed down with a wire brush to remove any loose, flaking paint and heavy corrosion before priming with Rust-Oleum 3369 CombiPrimer Anti-Corrosion. Following this, we would recommend applying Rust-Oleum CombiColor Original over the existing painted finish and the newly primed areas.

I hope this helps and please feel free to get in touch with any further questions.

Many thanks

Stuart

Hi

I want to renovate the rusty sills and underside of a family 4×4. I have read about wire brushing and applying rust-converter, followed by a zinc-rich primer and marine paint, but am not sure if applying a zinc-rich primer on to the rust-converter will affect the galvanic action of the primer. What would you recommend?

Hi Martin,

Many thanks for your question. We recommend the use of a Zinc Phosphate Primer over a Rust Converter before application of a protective topcoat, so the products we would recommend for your project are as follows:

Teamac Rust Converter

Teamac Zinc Phosphate Primer

Teamac Metalcote Plant Enamel

We would generally only recommend a Zinc Rich Primer when it would be left as a finish in place of hot dip galvanising.

I hope this helps and please feel free to get in touch if you have any further questions.

Many thanks

Stuart

Great advice and very prompt

Thanks Stuart

Hi. Any advice please ref primer and top coat suitable for marine engines after suitable rust conversion. Cast iron blocks, and pressed steel sumps.

What would you suggest for new pressed steel sumps?

Many thanks for your time. MC

Hi Matt,

Thank you very much for your question. A heat resistant paint would be most suitable if the parts are to be exposed to high temperatures, in this case we would either recommend Coo-Var Heat Resistant Black Enamel or Teamac High Temperature Aluminium.

Neither of these products require a primer (and also a primer would not survive the high temperatures).

If the parts won’t be subjected to high temperatures, the best option would be Teamac Zinc Phosphate Primer followed by Teamac Metalcote Plant Enamel, as the Metalcote Enamel will give resistance to oil and the Zinc Phosphate Primer will give better resistance against corrosion.

I hope this helps, and please feel free to get in touch if you have any further questions.

Many thanks

Stuart

We just cleared the major rust and old paint off of a steel I-Beam truss bridge with a combination of Bauer Surface Reconditioning Tools using 40 Grit Discs and Angle Grinders using Wire Cups. Then we cleaned with paint thinner and applied 3 coats of Rust-Oleum 7769402 Rusty Metal Primer.

Winter is setting in, with cold/wet days and overnight condensation of moisture on the steel. The new bridge decking will arrive shortly and a contractor is booked to install it.

Do we need to top coat the Rusty Metal Primer or is it durable enough to last for years on its own in our Blue Ridge Mountains weather?

If we must top coat, then what should we use that can be applied in the current cool/damp weather?

Hi Alan,

Many thanks for your question and for taking the time to read our blog.

Unfortunately Rust-Oleum Rusty Metal Primer isn’t available here in the UK, so on this occasion we would recommend seeking advice from a supplier in the US.

Apologies would couldn’t help this time and thank you again for getting in touch.

Many thanks

Stuart

Hi I have galvanised metal lintels above the window if my house. They are quite rusty. I have abraded the surface getting rid of lose rust. I have already used a rust converter on one if the sils.

I am really confused as to whether I should use a primer for ferrous or non ferrous metals. many designed for ferrous metals say not fir galvanised surfaces but if course my galvanised surface is already rusty in many places.

your guidance would be really appreciated.

Hi Roger,

Thank you very much for your question and for taking the time to read our blog post.

Our Technical Team have advised that for this application we would recommend all areas cleaned and any rusty areas wire brushed back to sound clean steel.

Any rusty areas should be primed using Rust-Oleum 3369/3380 CombiPrimer Anti-Corrosion and any galvanised areas (metal looking areas that aren’t rusty) primed with Rust-Oleum 3302 CombiPrimer Adhesion Primer.

We would then recommend the application of two coats of Rust-Oleum Combicolor Original.

Regarding the “Rust converted” area this can be primed with the Rust-Oleum 3369/3380 CombiPrimer Anti-Corrosion directly but unfortunately we wouldn’t be able to guarantee how well this would last. The best course of action would be to abrade this back to clean steel and prime with Rust-Oleum 3369/3380 CombiPrimer Anti-Corrosion, followed by two coats of Rust-Oleum Combicolor Original.

Unfortunately most industrial suppliers and manufacturers would recommend using the correct surface preparation and/or primers over the use of rust converters where possible for the best possible results.

I hope this helps and please feel free to get in touch if you have any further questions.

Many thanks

Stuart

Hi.

Can you recommend an anti-rust metal primer I could use with an airbrush to paint small areas and small parts – aluminium and stainless steel, before applying paint coats

Hi Charles,

Thank you very much for your question. The types of specialist paints and coatings we offer do not provide information on application via airbrush so we’re unsure if any of our products would successfully be applied via this method. Aluminium and Stainless Steel wouldn’t have an anti-corrosion primer applied to them as they technically are non-ferrous so it would be an adhesion primer that is applied. The product we could offer for you to try would be Zinsser Bulls Eye 1-2-3 but again I’m unsure if the application method would be suitable.

I hope this helps and please feel free to get in touch if you have any further questions.

Many thanks

Stuart

Hi, I live in coastal Florida. Trying to deal with about 40’ of rusted corner beads on the exterior of my white stucco home. The beads are rusting and bleeding through the stucco and running down the stucco as well. My plan is to knock down the paint/stucco to bare metal then treat with some type of brush on rust converter and/or rusty metal primer before I re-stucco then prime and paint the stucco surface. The metal beads are around a large window and also around a faux planter box below some of which is obstructed by white decorative columns making use of any spray type paint impractical. What type of liquid brush-on products do you recommend I use to convert & prime the rusted beads before I apply the stucco? What products do you recommend I use to prime/seal and patch by the stucco?

Hi Ann,

Thank you very much for getting in touch and for taking a look at our blog. As we only supply within the UK at present, for your project we would recommend contacting a local supplier for advice on this occasion due to the differing temperatures/humidity between coastal Florida and the United Kingdom.

Apologies we weren’t able to help this time.

Many thanks

Stuart

Good morning

I’m restoring a tin ceiling in a centry home that has rusty sections. Which primer would be best to stop the rust from spreading?

Thank you

Nick

Hi Nick,

Thank you very much for taking the time to read our blog and for getting in touch. As Tin does not rust it is possible that the substrate is steel or galvanised steel.

So we could offer the best advice please could you forward some photographs of the ceiling to [email protected] so we can confirm the substrate, and our Technical Team will be happy to help and advise.

Rust should be removed by abrasion and then a suitable primer or cold-galvanising product used. Once we have confirmed the substrate we will be able to advise further on the best products to use for your project.

I hope this helps and we look forward to hearing from you soon.

Many thanks

Stuart