Sika’s range of injections here at Rawlins Paints can be used to securely seal and waterproof leaks in concrete, masonry and natural stone structures.

There are a lot of choices when it comes to selecting the right injection material, however; choosing the right one will make your leaking structure watertight for the long term. See all of Sika’s products available here at Rawlins Paints or, with the help of Sika’s guide below, find the optimal injection solution for your project requirements, with explainations for what injections are and the various solutions they provide.

Quick Links – Click To Jump To Section:

- Leaking Cracks / Penetrations Dry and / or Containing Water

- Leaking Expansion Joints (movement) and Construction / Daywork Joints (non-moving)

- Leaking Membrane Compartment Systems

- Leaking Wall / Kicker Areas

- What Are Injections?

- Why Choose Sika Injections?

- Successful Waterproofing with Sika Injection Systems

- The Many Advantages of Sika Injection Solutions

- The Different Injection Materials

- Sika Injection Product Links

Leaking Cracks / Penetrations Dry and / or Containing Water

Image courtesy of Sika

| Requirements | Criteria | Suitable Sika Injection Products |

|---|---|---|

| Waterproofing cracks and around penetrations of width > 0.2 mm with hydrostatic pressure | Fast and stable foaming and expansion, for temporary sealing, plus very low viscosity and long-term flexibility for permanent sealing and waterproofing. | Sika Injection-101 RC (for temporary sealing) followed by: |

| Sika Injection-201 CE (for permanent flexible sealing) | ||

| Sika Injection-107 (for permanent flexible sealing) | ||

| Waterproofing cracks and around penetrations of width > 0.2 mm without hydrostatic pressure (dry, damp or wet surfaces) | Very low viscosity and long-term flexibility for permanent sealing. | Sika Injection-201 CE /-107 (for permanent flexible sealing) |

| Force transfer across dry cracks of width > 0.3 mm | Low viscosity, rigid, excellent adhesion and full bond to the crack substrate surfaces for structural bonding. | Sikadur-52 |

| Force transfer across dry cracks of width > 0.1 mm | Very low viscosity, rigid, excellent adhesion and full bond to the crack substrate surfaces for structural bonding. | Sika Injection-458 |

Leaking Expansion Joints (movement) and Construction / Daywork Joints (non-moving)

Image courtesy of Sika

| Requirements | Criteria | Suitable Sika Injection Products |

|---|---|---|

| Waterproofing construction joints with and without hydrostatic pressure | Fast and stable foaming and expansion for temporary sealing, plus very low viscosity and long-term flexibility for permanent sealing and waterproofing. | Sika Injection-101 RC (optional for temporary sealing in case of hydrostatic pressure) followed by: |

| Sika Injection-201 CE (for permanent flexible sealing) | ||

| Sika Injection-107 (permanent flexible sealing) | ||

| Waterproofing joints where the original joint sealing / waterproofing system is damaged or was not properly installed | Pre-installed SikaFuko® injection hose system in construction joints or as a back-up system on waterbars: Very low viscosity, long term flexibility, long pot-life for optimum penetration, re-injectable for permanent sealing | |

| Sika Injection-307 (for permanent flexible sealing in steel concrete) | ||

| Sika Injection-310 (for permanent flexible sealing) | ||

| Sika InjectoCem-190 (for use in dry areas only) | ||

| Damaged expansion sections of waterbars: Low viscosity, long term high flexibility, with adjustable reaction times for permanent sealing. | Sika Injection-307 (for permanent flexible sealing) in steel concrete | |

| Sika Injection-304 (for permanent flexible sealing) |

Leaking Membrane Compartment Systems

Image courtesy of Sika

| Requirements | Criteria | Suitable Sika Injection Products |

|---|---|---|

| Waterproofing damaged and leaking sheet membrane compartment systems | Low viscosity, tough-elastic, very easy to use, re-injectable for permanent sealing | Sika Injection-310 (for permanent flexible sealing) |

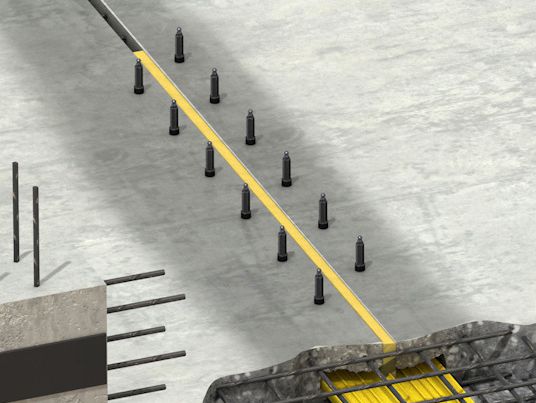

Leaking Wall / Kicker Areas

Image courtesy of Sika

| Requirements | Criteria | Suitable Sika Injection Products |

|---|---|---|

| Grid injection (into the surface for larger areas e.g. Honeycombing or poor concrete compaction etc.) | Low viscosity, void filling, rigid material for load transfer in both (dry and damp areas) | Sika InjectoCem-190 (dry area) / (optional, patch repairs with Sikadur-31 CF) |

| Very low viscosity, flexible, designed for permanent sealing (in wet areas) | Sika Injection-307 /-304 / (optional, patch repairs with Sikadur-31 CF) | |

| Sika Injection-201 CE /-107 / (optional, patch repairs with Sikadur-31 CF) | ||

| Curtain injection (e.g. behind the structure or element to seal leaks due to multiple tie bar holes or other multiple minor defects / leaks) | Extremely low viscosity, highly flexible, adjustable reaction time, designed for permanent sealing | Sika Injection-304 |

What Are Injections?

Injections secure leaks, repairing compromised structures making them long-term watertight by pumping cement-based, polyurethane-based, epoxy-based or acrylate-based material into cracks and other signs of damage on structures.

Why Choose Sika Injections?

- Avoids the expensive cost of structural repair

- Reduces operational downtime

- Used for all types of leak-sealing in concrete, masonry and natural stone structures

- Forms a new permanent watertight seal

- Used at any time such as during initial construction or later to extend the service life during any subsequent repair or renovation, depending on the project’s specific requirements

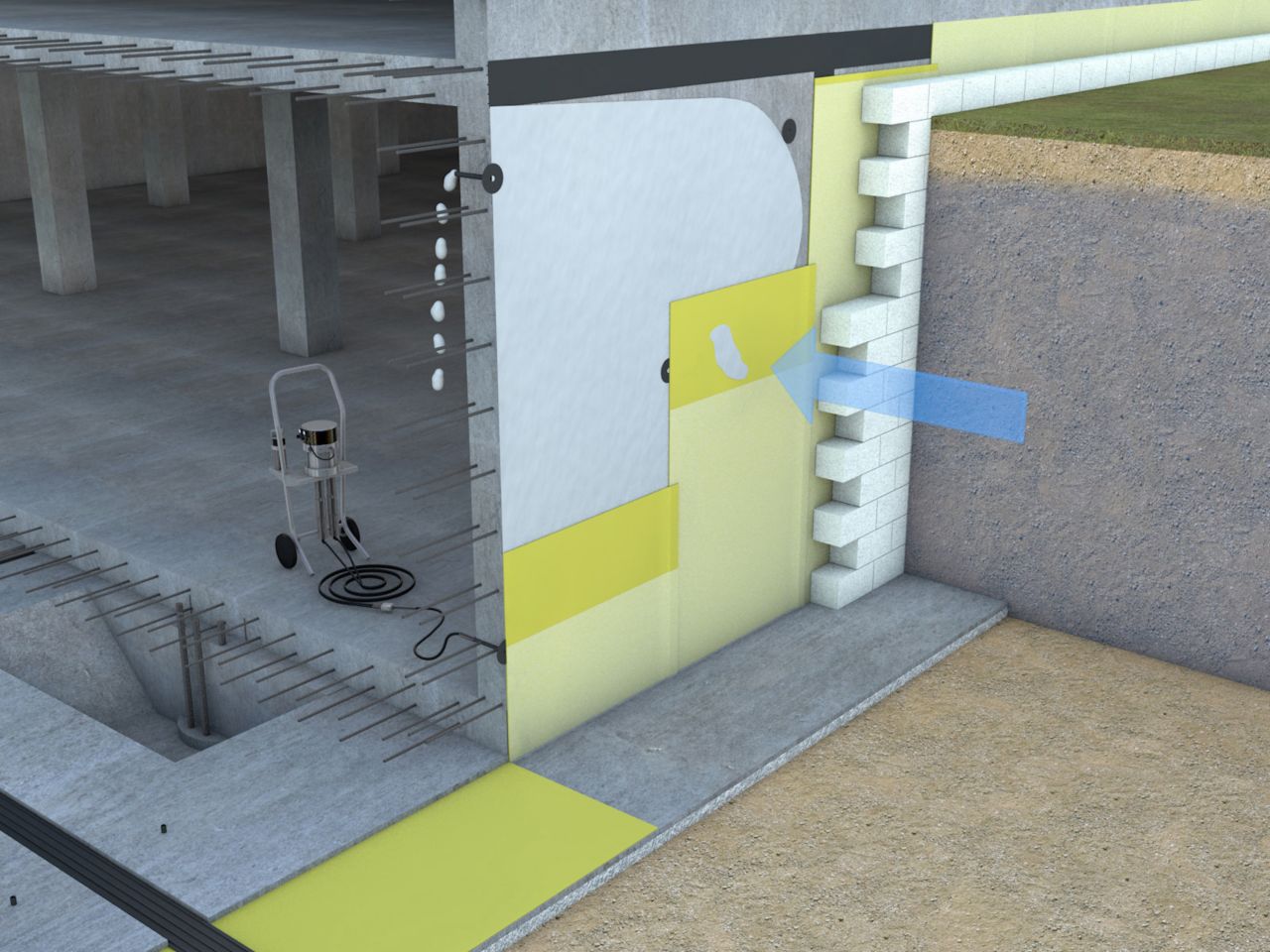

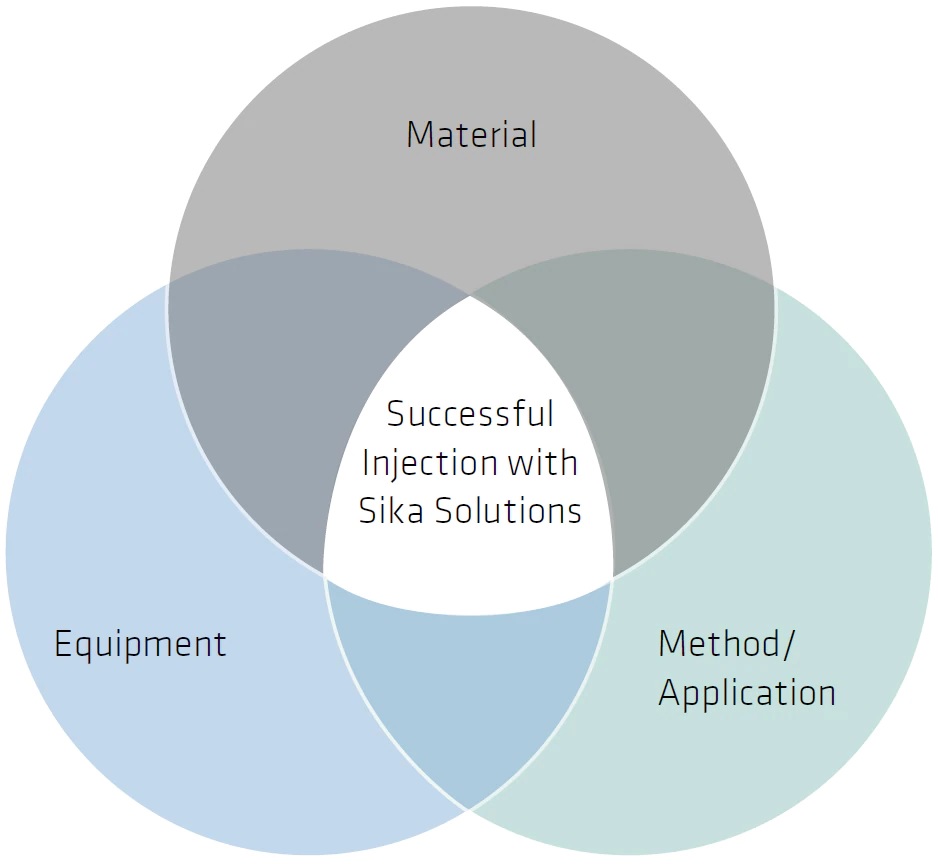

Successful Waterproofing with Sika Injection Systems

Image courtesy of Sika

Three factors are involved in ensuring an effective and durable injection project; the right combination of injection materials, injection equipment and injection method should be selected.

Sika’s extensive technical and practical experience provides:

Injection Material

The (first) key factor for success, the defined project requirement needs a selection of the right injection material and the right specific injection product, with the material’s viscosity, flexibility and behaviour in contact with water especially important. All these factors can significantly influence the effectiveness of the injection.

Injection Equipment

The appropriate equipment for material preparation, mixing and delivery of the selected injection material – which includes the initial dosage and mixing, delivery from a suitable pump, to use of the right packers/ ports/ connectors – is the second key factor for a successful injection.

Injection Method / Application

Using trained, skilled and experienced contractors that follow the correct injection method and application techniques should provide a successful and complete, permanent leak-sealing solution.

The Many Advantages of Sika Injection Solutions

- An extensive range of injection materials for all types of leak-sealing applications

- Tested and approved injection solutions to the leading global standards

- Expert technical advice and support

- Selected Sika injection systems can also be used to increase or restore structural integrity and load-bearing capacity

- Fully compatible with Sika’s complete engineered waterproofing systems.

The Different Injection Materials

Polyurethane foam resins

Image courtesy of Sika

- Expands with water

- Temporarily blocks passage of water through the crack or void

- Forms a tough and flexible elastic foam with a fast-expansive reaction with water

- Re-injected with a suitable non-foaming injection resin, usually also based on polyurethane, for permanent waterproofing.

Polyurethane Resins

Image courtesy of Sika

- Hydrophobic

- Flexible

- Used for non-structural injection sealing and waterproofing voids, cracks and joints.

- Low viscosity

- Good penetration into concrete structures

- Seal leaks and achieves a durable elastic seal

- Very strong edge adhesion to concrete

- In voids, cracks and joints with high water ingress, pre-injection as temporary water stopping with a polyurethane foaming resin is required.

Acrylate Resins

Image courtesy of Sika

- Hydrophilic

- Very flexible

- Used for non-structural injection of cracks, joints and voids, including injection hose systems, compartment systems and area injections (e.g. grid and curtain)

- Extremely low viscosity (similar to water)

- Ideal penetration abilities with adjustable reaction or hardening time

- Flexibility to adapt to prevailing conditions on site (temperature and injection distance, for example)

- Seals and waterproofs leaks through hydrophilic swelling behaviour in contact with water

- Injection equipment can be easily cleaned with water

Epoxy Resins

Image courtesy of Sika

- Relatively high tensile and compressive strengths in relation to concrete

- Generally regarded as ‘rigid’ materials and widely used for structural repairs by injecting cracks and voids in load bearing reinforced concrete structures or elements

- Low viscosity allows excellent penetration into cracks and strong adhesion to concrete

- Helps to ensure permanent and durable load transfer

- Suitable for many different structural injection requirements and applications in dry to slightly damp conditions

Microfine Cement Suspension

Image courtesy of Sika

- Non-flexible

- Non-movement-accommodating

- Rigid

- Polymer-modified

- Also known as microfine cement grouts

- Based on blended microfine cement

- Widely used for structural injection to seal non-moving cracks, voids and construction joints

- High flow characteristics

- Very good penetration ability

Sika Injection Product Links

Find Sika Injections here at Rawlins Paints:

Rawlins Paints Blog Industrial Paint Tips, Guidelines & DIY Articles

Rawlins Paints Blog Industrial Paint Tips, Guidelines & DIY Articles