Heskins Safety-Grip is a tough, durable, self-adhesive anti-slip material for providing extra grip on a wide range of surfaces, including porous substrates, such as steps and stair nosings. Ideal for pedestrian traffic or light vehicular traffic, Safety-Grip is very easy to apply and can be used on most surfaces, making it particularly useful for workplaces - even on the forks of forlift trucks - and has even been used at events such as Red Bull's Cliff Diving and during BMX trials at the Rio 2016 Olympics, London 2012, and Baku 2015.

Once applied correctly (following Heskins' procedures) by simply removing the backing tape and pressing into position, Safety-Grip provides grip even if oil, water or other contaminants are present, and is fully effective after 48 hours. The tape has been used in extreme and challenging environments, including the tops of wind turbines to aid inspection and maintenance, and upon the Mundo Marino Platu 25 boat during competition. One company coated the flat surfaces of their waste-disposal bins with Safety-Grip to prevent stickers, posters and flyers from being stuck on the sides.

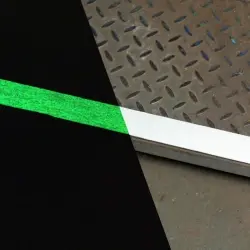

The Safety-Grip range is available in many thicknesses and sizes with Transparent, Fluorescent Yellow, Hazard schemes in red/white and black/yellow, Camouflage, and Glow In The Dark Photoluminescent available. The material comes on rolls in sizes up to 1150mm x 18.3m, depending on colour, as well as pre-made shapes, such as feet and boot outlines, available on Heskins Safety-Grip Anti-Slip Tape Shapes.

Check out the videos above for applications instructions to different substrates and surfaces, or contact our technical team for more information on 0113 2455450.

See the Heskins range of accessories for additional help during application, pro-longing the life of anti-slip tapes and line markings. The range consists of primers, edge fixing, mallets, rollers etc.

For application on irregular surfaces, such as ribbed decking, see Heskins Conformable Safety-Grip or Heskins Safety-Grip Bolt Down Plates.

Features & Benefits

- Tough and durable anti-slip material

- Adheres to most surfaces (follow Heskins' procedures)

- Ideal for steps, stairs and walkways

- Use with Heskin's Bolt Down Plates to apply to decking

- See video above for details

- High levels of Coefficient of Friction - details further below

- Made of abrasive aluminium oxide particles

- See safety data sheets in the Attachments section for more test results

- Very easy to apply

- Withstands most chemicals present in commercial environments

- Excellent resistance to motor oil

- R118 Approved

- Shapes including boots and feet cut-outs available on Heskins Safety-Grip Anti-Slip Tape Shapes

- Glow In The Dark Safety Grip also available.

Ordering References

Contact our sales team by email or on 0113 2455450 to order custom shapes, sizes and cuts, which can be made to order in most RAL colours. Please note that these may have an extended lead time.

Standard Grip

Colours

Includes Black, Brown, Fluorescent Yellow, Green, Grey, Orange, Red, White, Yellow, Blue and Transparent.

Available sizes:

- 18.3m rolls, between 25mm and 1150mm widths

Hazard

Includes Red/White (RAL3000 & 9016) and Black/Yellow (RAL1023 & 9017).

Available sizes:

- 18.3m rolls, between 25mm and 550mm widths

Camouflage

Available sizes:

- 18.3m rolls, between 25mm and 1150mm widths

Coarse Grip

The coarser Safety Grip provides a surface more resistant to clogging from dust and mud, making it ideal for use on construction and building sites.

The grit is still the same substance, aluminium oxide; the grit granules are larger with deeper valleys and higher peaks. A deep anti slip coating helps to prevent clogging with dirt, dust, ice etc.

Colours

Includes Black and Yellow.

Available sizes:

- 18.3m rolls, between 25mm and 1150mm widths

Hazard

Includes Black/Yellow (RAL1023 & 9017).

Available sizes:

- 18.3m rolls, between 25mm and 550mm widths

Extra Coarse

Designed for heavy duty, industrial use, the extra-coarse Safety Grip copes with harsh environments and heavy use.

Available in Black or Green, in the following sizes:

- 18.3m rolls, between 25mm and 1150mm widths

Product Details

The material is constructed from a self-adhesive plastic base film.

The adhesive is pressure sensitive and is protected by a siliconised treated release paper.

The upper surface consists of abrasive aluminium oxide particles held in place by a polymer resin. Prior to setting, the granules are charged by static electricity to help point upwards thus increasing grip levels.

When applied, Safety Grip will typically last 3 years, and can be incinerated or disposed of through conventional methods; the waste disposal code is 20.01.04.

Application Instructions

These instructions can be downloaded in the attachments tab above, along with more safety data and test results.

For best results follow the instructions below to ensure maximum performance in all environments.

- Material Storage - Ensure the material is kept in dry, warm conditions in the original protective packaging.

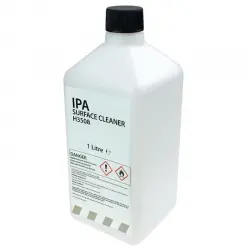

- Surface Preparation - A clean, dry surface is essential. Use an IPA cleaner to remove all surface contaminants (paint flakes, etc) – DO NOT use methylated spirits/petrol/lighter fluid etc as these leave behind a thin, greasy residue. Ensure prepared surface is above 10°C.

- Porous Surface Sealing - Porous surfaces must be sealed prior to application to prevent water attacking the adhesive. Toluene based primers are ideal - we recommend Heskins own H3506 Primer for this job. Apply a thin coat to the cleaned surface using a paint brush, then leave to dry.

- Tape Application - Peel back part of the release liner then press the adhesive firmly onto the prepared surface, and slowly keep peeling back the liner while applying the tape. Try to ensure that the tape is not taut.

- Finish! - Once applied, press tape down firmly using even pressure (decorating rollers are excellent for this). We recommend sealing the edges using ‘edge fix’ as this will extend the life of the product. Only use a small amount down the edges, a thin bead.

If correctly applied, the new anti-slip surface can be walked on instantly, you will get maximum benefit from the adhesive system after 48 hours.

Safety Data & Test Data

| Subject | Result | Test Method |

|---|

| Back carrier | 0.1mm PVC | Calliper method |

| Type of adhesive | Solvent acrylic | N/A |

| Mineral type | Aluminium Oxide | N/A |

| Adhesion to steel (g/25.4mm²) | 1500↑ | PSTC-4 |

| Tensile strength (Kg/25.4mm²) | 6.0↑ | PSTC-31 |

| Tear resistance (g) | 5600 +/- 200 | PSTC-39 |

| Peel adhesion, N/25mm | 23.5 | 180° FINAT FTM1 |

| Tensile strength, N/25mm | 68 | Lloyd, 500N load cell |

| Elongation at break | 25%↑ | PSTC-31 |

| Temperature range | -40ºC to +70ºC | See notes below |

| Maximum size of production roll | 1168mm x 100m | N/A |

| Resistance to water (months) | 10 | PSTC-35 |

| Resistance to chemicals (months) | 8 | PSTC-35 |

| Resistance to motor oil | Excellent | PSTC-35 |

The independent test laboratory at Adhesive Technical Services Ltd performed the temperature test, England (test results available on request)

For more in-depth safety and test data, please refer to the attachments above, or give our technical team a call on 0113 2455450.

| Coefficient of friction data |

|---|

| Safety-Grip | Dry surface test result | Wet surface test result |

| Standard | 102 TRL | 71 TRL |

| Coarse | 99 TRL | 80 TRL |

| X-Coarse | 102 TRL | 80 TRL |

R118 approved

This is a test to determine “the burning behaviour and/or the capability to repel fuel or lubricant of materials used in the construction of M3 category vehicles classified II or III.”

Heskins Safety Grip was put through 3 out of the 5 tests that are in the R118 regulation (not all are required to pass). As detailed on the R118 certification, the material was subjected to Annexe 6, 7 and 8.