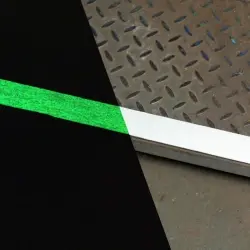

Heskins Safety Grip Photoluminescent self adhesive anti slip tape is a tough and durable, self-adhesive anti-slip material that glows in the dark. Use it to provide extra grip on a wide range of surfaces, specifically as an anti slip tape for stairs and stair nosings, and as a visual aid on floors and around doors in areas prone to power failure, guiding personnel in lights-out situations. Glow in the dark shair nosing, shapes and boot outlines can be ordered separately. The photoluminescent material charges from both natural and incadescent (artificial) light, making it an ideal choice for warehouses and workshops, and is available in a plain design, a glow line, or in a hazard pattern.

When the lights go out in an emergency, there’s still an obligation to mark exits and hazards. Heskins Glow In The Dark tapes are highly photoluminescent and allow clear marking of exits and hazards when the lights go out.

Ideal for pedestrian traffic or light vehicular traffic, Safety Grip self adhesive anti slip tape is very easy to apply and can be used on most surfaces, making it particularly useful for workplaces. Once applied correctly (following Heskin's procedures), Safety Grip self adhesive anti slip tape provides grip even if oil, water or other contaminants are present.

The Safety Grip range is available in many thicknesses and colours, including Transparent, Fluorescent Yellow, Hazard schemes in red/white and black/yellow, and Glow In The Dark Photoluminescent. The material comes on rolls (from 19mm up to 1168mm) as well as pre-made shapes; more sizes and custom cuts, shapes and colours can be made to order - contact our sales team by email or on 0113 2455450.

See also:

See the Heskins range of accessories for additional help during application, pro-longing the life of anti-slip tapes and line markings. The range consists of primers, edge fixing, mallets, rollers etc.

Features & Benefits

- Self adhesive anti slip tape

- Tough and durable anti-slip material - non-abrasive

- Photoluminescent tape glows in the dark, charging by natural or artificial light

- Does not harbour bacteria - ideal for hospitals and clean rooms

- Adheres to most surfaces (follow Heskin's procedures)

- Ideal as a non slip tape for stairs, steps and walkways prone to power failure

Helps personnel find direction in blackout

- High levels of Coefficient of Friction - made of abrasive aluminium oxide particles

- Very easy to apply

- Withstands most chemicals present in commercial environments

- Meets DIN, ASTM and OSHA requirements

- Stair nosings and ready-cut shapes, including boots and feet outlines, available separately

- Custom shapes, sizes and cuts can be made to order

Ordering References

Stair nosings and ready-cut shapes, including numbers, boots and feet outlines, are available separately.

H3403X Safety-Grip - Glow in the Dark

Available in the following sizes:

- 25mm x 18.3m

- 50mm x 18.3m

- 100mm x 18.3m

H3403D Safety-Grip - Hazard Glow in the Dark

Available in the following sizes:

- 25mm x 18.3m

- 50mm x 18.3m

- 100mm x 18.3m

H3403N Safety-Grip - Glow Line

Glow Line has a 10mm centre glow strip, with 20mm black either side.

Available in the following sizes:

How It Works

Glow In The Dark tape is charged by absorbing artificial or natural light. After around 2 hours exposure to a suitable light source the tape emits a photoluminescent glow that can help personnel identify key features along an exit route.

Under normal lighting photoluminescent tapes will appear a mild green and in darkness they will be white.

The Glow In The Dark materials used to manufacture Heskins products are non-toxic, and free from any phosphorous or radioactive material.

Product Details

The material is constructed from a self-adhesive plastic base film.

The adhesive is pressure sensitive and is protected by a siliconised treated release paper.

The upper surface consists of abrasive aluminium oxide particles held in place by a polymer resin. Prior to setting, the granules are charged by static electricity to help point upwards thus increasing grip levels.

The product is photoluminescent, both the film and the resin are treated. The product is charged by either natural or incandescent lighting. None of the components are radioactive.

When applied, Safety Grip will typically last 3 years, and can be incinerated or disposed of through conventional methods; the waste disposal code is 20.01.04.

Safety Data & Test Results

| Subject | Result | Test Method |

|---|

| Back carrier | 0.1mm PVC | Calliper method |

| Type of adhesive | Solvent acrylic | N/A |

| Mineral type | Aluminium Oxide | N/A |

| Adhesion to steel (g/25.4mm²) | 1500↑ | PSTC-4 |

| Tensile strength (Kg/25.4mm²) | 6.0↑ | PSTC-31 |

| Tear resistance (g) | 5600 +/- 200 | PSTC-39 |

| Peel adhesion, N/25mm | 21.1 | 180° FINAT FTM1 |

| Tensile strength, N/25mm | 95.7 | Lloyd, 500N load cell |

| Elongation at break | 25%↑ | PSTC-31 |

| Temperature range | -40ºC to +70ºC | See notes below |

| Maximum size of production roll | 1168mm x 100m | N/A |

| Resistance to water (months) | 10 | PSTC-35 |

| Resistance to chemicals (months) | 8 | PSTC-35 |

| Resistance to motor oil | Excellent | PSTC-35 |

The independent test laboratory at Adhesive Technical Services Ltd performed the temperature test, England (test results available on request)

Glow in the dark safety-grip® results

30 millicandela per m² at 2 minutes, 5mcd after 10 minutes

| Coefficient of Friction Data |

|---|

| Safety-Grip® | Dry Surface Test Result | Wet Surface Test Result |

| Standard | 102 TRL | 71 TRL |

The above tests were conducted in accordance with Pendulum, the tests were conducted at a recognised independent friction testing laboratory, and copy certificates are available on request. Pendulum is a dynamic test, for static tests, we also have results ASTM C 1028-96.

All the above data is for reference only.

R118 approved

This is a test to determine “the burning behaviour and/or the capability to repel fuel or lubricant of materials used in the construction of M3 category vehicles classified II or III.”

Heskins Safety Grip (Glow In The Dark and Hazard, not Glow Line) was put through 3 out of the 5 tests that are in the R118 regulation (not all are required to pass). As detailed on the R118 certification, the material was subjected to Annexe 6, 7 and 8.