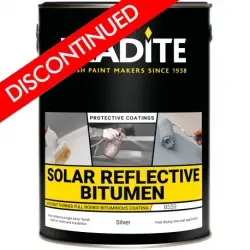

We no longer stock this product, but can recommend Coo-Var Solar Reflective Paint Aluminium as a great alternative.

We no longer stock this product, but can recommend Coo-Var Solar Reflective Paint Aluminium as a great alternative.

Bradite Solar Reflective Bitumen is a gloss coating intended for substrates which are dry and free of contamination. It works by furnishing a tough hard-wearing film over the substrate that provides excellent water repellency. Silver in colour, the coating offers solar reflective properties on:

With the exception of fish ponds and drinking water, this coating is ideal for water immersion systems, such as water storage, and many a usage within industrious environments can be found with this in mind.

Manufactured under the auspices of an ISO 9001:2008 quality & ISO 14001:2004 environmental management systems.

If you don't require the solar reflective component, you can choose the black version, please see Bradite Bitumen Coat/Finish (BB58)

High pressure steam cleaning to remove all loose, flaking paint and contamination back to a sound surface. Bradite TD39 industrial strength detergent, washing and rinsing should be used with scrubbing to remove grease or oil.

Remove all rust scale, loose mill scale or other corrosion products by scraping and mechanical cleaning to SIS-St 3 (ISO 8501-1:1998).

Intact areas of existing coatings should be roughened by abrasive manual or disc sanding, feathering back to a sound coating edge. Cracks and pits should be filled using a suitable metal filler before painting. Substrate should be dust free and completely dry before coating.

Application and use should always conform to the codes of practice described in BS 6150 and BS 5493

Brush and Roller: supplied ready for use. Use natural bristle brush, tapered and flagged, for best appearance. Thin, if required, with 0-5% Bradite Thinner TW35.

Conventional Air Spraying: Thin with 0-25% Bradite Thinner TW35 as required, tip size – 2.0 mm, tip pressure 60psi (0.4MPa) approximately.

Airless Spraying: Thin with 0-10% Bradite Thinner TW35 as required, tip size - 23 thou (0.58mm) approximately, tip pressure - 2100 psi (15MPa) approximately.

Clean all equipment immediately after use with Bradite Thinner TW35 for best results.

Customer agrees that before placing an Order, Customer has read and understood the most up to date Product Data Sheet for the Product. Where we have access to the Product Data Sheet from the manufacturer, we will either provide a copy on request, or include a link to the Product Data Sheet available on the manufacturer’s website. Customer further agrees that we have no liability for any errors or omissions contained within the Product Data Sheets. For more information, please see our Terms & Conditions of Sale.

Bradite Solar Reflective Bitumen is only available with the shipping and delivery timescales listed below - please do not contact our Customer Support Team with enquiries about alternative or earlier shipping and delivery times.

Saturdays and Sundays, as well as Bank Holidays, are not classed as working days.

Orders placed after the cut-off for this product will not be processed for earliest dispatch until 9am the next working day.

All delivery costs below are excluding VAT