Zeroflame Fire Retardant Paint is a waterborne fire protection coating for interior use. This coating has been successfully tested on a variety of timber substrates to BS EN13501-1:2007 achieving B s2 d0 (replaces UK Classes ‘0’ and ‘1’ BS 476 Part 6/7*). It is suitable for use over sound existing coatings and can be over-coated with waterborne, non-flammable paints where a decorative finish is required. This single-pack, waterborne product is extremely simple to use.

Zeroflame Fire Retardant Paint can be applied to reduce the ignitability of soft and hard wood and other wood derivatives, i.e. plywood, chipboard, fibre insulation board, hard board, also on veneering ≥ 12mm thickness. Insulates against heat, checks fire, prevents propagation of fire and diminishes flue-gas density and flue-gas temperature. For interior use only, not suitable for surfaces exposed to mechanical stress.

Please click here for Zeroflame's fire retardant paint for steel surfaces or here for Zeroflame Fire Retardant Treatment (a clear solution that soaks into bare wood to leave the appearance of the timber virtually unchanged).

Quick Links - Click To Jump To Section:

Features & Benefits

- Water based

- Apply by brush, roller or spray

- Achieves Euroclass B s2 d0 (replaces UK Classes 0 and 1 BS 476 Parts 6/7)

- Matt white finish

- When overcoating use only waterborne, non-flammable paints (Please test on a small area before treating the complete surface to ensure you are satisfied with the result)

- Can be applied over sound existing coatings

- Has a coverage rate of 3.7m² per litre (allows for the 2 coats that need to be applied)

Where To Use

- Timber, tongue & groove, masonry, plaster, plaster board, MDF, over sound existing coatings, etc.

- Commercial and domestic environments, including: airports, restaurants, railways stations, housing, flats, shopping centres, community housing, ceilings, etc.

Certification

Zeroflame Fire Retardant Paint has been tested to BS EN13501-1:2007 on timber and composite wood substrates, B s2 d0 being obtained.

To receive a 'Certificate of Supply' for your purchase, after application of the product, simply complete the form HERE and a certificate will be returned to you within 7-10 working days.

Technical Information

| |

|---|

| Appearance When Dry: | Matt White |

| Mass Density: | Approx. 1.29 g/cm³ |

| Solids by Weight: | Approx. 65% (according to EN ISO 3251) |

| VOC Content: | Max. 0g/litre (2010 EU limit: 140g/litre) |

| Shelf Life: | 12 months from delivery in cool and dry storage conditions and in original unopened containers |

| Wet Film Thickness: | 270 microns |

| Dry Film Thickness: | 170 microns |

Preparation

Stir Zeroflame Fire Retardant Paint thoroughly until free of lumps. Substrates must be dry (moisture content must not exceed 15%), free from dust, wax, grease, dirt, resin, etc. Existing coatings with poor adhesion must be completely removed. Coatings containing lime, chalk or lithopone should be removed.

Application

Wet film thickness (WFT): 270 microns; Dry film thickness (DFT): 170 microns.

Airless Spray

- Zeroflame Fire Retardant Paint should be applied undiluted

- Airless spray equipment with pressure ratio 30:1

- Hose diameter not below 3/8"

- Whipline 1.5-2m. NW6 may be used

- Recommended tip size 0.34-0.66mm or 0.017-0.027

- Hoses must be used only for water based coatings

Brush/Roller

- Zeroflame Fire Retardant Paint should be applied in supplied viscosity

Conditions

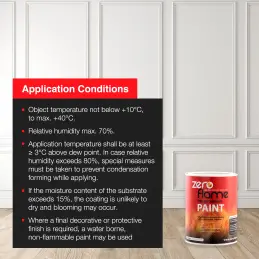

Object temperature not below +10°C, to max. +40°C, relative humidity max. 70%.

Application temperature shall be at least ≥ 3°C above dew point. In case relative humidity exceeds 80%, special measures must be taken to prevent condensation forming when applying. If the moisture content of the substrate exceeds 15%, the coating is unlikely to dry and blooming may occur. Moisture content should be at, or near that anticipated when in use.

Drying

At approx. 20°C temperature and 65% relative humidity approx. 6 hours. Lower temperatures and higher relative humidity may extend drying times. Allow 48 hours before overcoating.

Cleaning

Immediately after use, clean the equipment with water.

Health & Safety Information

Please observe safety instructions on container labels and local regulations. Dangerous Goods regulation should be followed. During application in closed rooms, pits and shafts, etc. sufficient ventilation must be provided. Keep away from naked flame, including welding. In poorly lit rooms, only electric safety lamps are permitted. The installed ventilation equipment must be spark-proof. In a liquid or not fully cured state, the product contaminates water and should not be allowed to enter drains or be spilled onto open ground. All spillages and liquid waste must be removed according to local health and safety regulations.

For full details on Health & Safety data for this product, refer to the Safety Data Sheet available to download from the above ‘DATA SHEETS’ tab.

* This product has not been tested to BS 476 Parts 6 & 7, Class 1/0 so if this is the level of protection you require you should check with your authority prior to use that they will accept BS EN 13501-1:2018 B s2 d0 as a suitable alternative before proceeding.

IMPORTANT FIRE PRODUCTS NOTICE: The information displayed on this website should be used as a guide ONLY and our Technical Department should be contacted to obtain a tailored specification and any advice necessary before you place an order for fire protection products. Fire protection products are non-returnable except in accordance with Condition 8 of the Terms and Conditions and should be applied only by an individual with the necessary expertise and experience. We will not be held liable for any resulting damage to property, human life or monetary costs incurred due to the incorrect specification you have prepared or use of fire protection products caused by your negligence, including your failure to have contacted us to obtain the relevant advice/specification.