Resuflor SL F (formerly known as Epo-Flex FX and Resuflor FX) is a 3-part self-smoothing polyurethane modified epoxy resin floor finish designed to provide a hard wearing gloss finish between 2.5 - 3 mm thickness, which has a degree of seamless flexibility for industrial use.

- Recommended uses:

- Buildings with plywood or chipboard floor substrates

- Retail outlets

- Printing and packaging areas

- Television studios

- Mezzanine areas

- Nightclubs

- Domestic studios

Features & Benefits

- Formerly known as Epo-Flex FX and Resuflor FX

- 3-part

- Tough & seamless with a degree of flexibility

- Hard wearing durable floor for industrial use

- Ease of application

- Hygienic

- Decorative - available in an attractive range of colours

- Excellent abrasion and impact resistance

- Good chemical resistance

- Smooth finish for precise operating equipment

Product Information

| Product Information |

|---|

| System Thickness (Recommended) | 2.5 - 3mm |

| Solids Content by Weight | 100% |

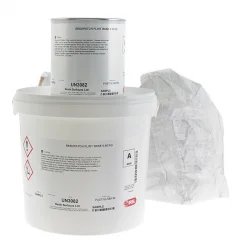

| Pack Make Up | 1 x Base, 1 x Hardener, 1 x Filler SL1 Aggregate |

| Shelf Life | 36 months (Base, Hardener & Aggregate) |

| Storage | Keep out of direct sunlight. Store in a dry place, not below 15°C. |

| Application Information (at 20°C) |

| Coverage Rate (Theoretical) | 5 sq m per 29.5kg unit @ 3mm thickness. |

| Coverage rate is calculated based on a sealed and smooth surface and may vary based on the substrate roughness and other conditions. |

| Pot Life | 30 minutes |

| Recoating Intervals | 24 - 32 hours |

| Light Traffic | 48 hours |

| Full Traffic | 96 hours |

| Full Chemical Cure | 10 - 14 days |

| Technical Information |

| Category Guide | FerFA Category 5 |

| Slip Resistance | Dry > 50 |

| Method BS7976 pt1-3 2002 | Wet - Please consult Sherwin-Williams/Rawlins Paints Technical |

| The slip resistance of a floor surface can vary as a result of the installation process, conditions at the time of application and subsequent traffic. Inappropriate cleaning or maintenance can adversely affect the performance. For further advice on potential wet areas please consult Sherwin-Williams/Rawlins Technical |

| Abrasion Resistance (BS EN 13892-4:2002) | AR 0.5 |

| Temperature Resistance | Tolerant of temperatures up to 60°C |

| Chemical Resistance | Good Chemical Resistance - Consult Sherwin-Williams/Rawlins Technical on specific materials |

| VOC | 95 g/l calculated per full mixed unit |

| Life Expectancy | Up to 5 years (Subjected to Industrial Traffic) - Sherwin-Williams terms and conditions will apply. |

Products required for this system

- Primer : Resuprime ST / Resuprime MVT

- System : Resuflor SL F at required thickness

- Surface Seal : Not required

- (Optional Resupen WB Matt for a matt finish or Resudeck with aggregate for a non-slip finish)

Preparation

New Concrete Floors:

New concrete must be clean, sound, dry, fully cured and surface laitance removed by vacuum enclosed shot blasting or mechanical grinding, a minimum strength of 25N/mm² is required.

Existing Concrete Floors:

Remove all dirt, oil, grease, old paint or any other surface contaminants by vacuum enclosed shot blasting, scarifying or mechanical grinding. Fats, oils or greases must be removed by mechanical means and detergent washing and make sure all residue of detergent is washed and removed by rinsing with clean water. Local repairs should be carried out using Resuscreed PA.

Existing Floors ( previously coated )

All previous coatings and loose floor paints must be removed by mechanical preparation as described in the above section and primed as specified. if the old resin flooring cannot be removed, then please consult with our technical team for advice on intercoat adhesion and suitability, as it may not be compatible with existing floor coating.

Where over-coating other systems such as epoxy coatings or screeds, as part of a specified composite system in the data sheets, please follow the recoat time as stated in the individual data sheets, the coating in each stage should be tack free, but not fully cured. If fully cured then mechanical preparation is required to ensure intercoat adhesion.

Timber Floors

Must be clean, sound, dry. Old clear varnish/topcoat must be removed/sanded prior to application, as it may affect the inter- coat adhesion with Resuflor SL F.

Priming

Open and porous substrates will require priming with Resuprime ST, on dry substrates only with less than 75% ERH reading.

Where the Relative Humidity of a substrate exceeds 75% ERH Resuprime MVT should be specified and selected on the basis of hygrometer readings in accordance with BS 8203. The number of coats to be applied is chosen in accordance with the following table.

| ERH% | Required Coating Thickness |

|---|

| 75-85 | 1 coat of Resuprime MVT at 200 microns per coat |

| 85-92 | 2 coats of Resuprime MVT at 200 microns per coat |

| 92-97 | 3 coats of Resuprime MVT at 200 microns per coat |

For further information please refer to individual product data sheets.

Application

The ambient temperatures of the areas should not be allowed to fall below 15°C throughout the application and the curing period, as this could have an adverse effect on the appearance and colour of the system. Surface temperature must be above 10°C.

Where possible it is recommended that the application area is heated to a minimum temperature of 15°C ideally to allow the ambient and substrate temperature to stabilise prior to installation.

Mixing

Pre-mix the coloured component (base) to a uniform colour, then mix the entire contents of base with the hardener. If a separate mixing bucket is being used, ensure all contents of both components are removed from the buckets supplied. Mix using a slow speed electric mixer for approximately one to two minutes until the two components have fully combined then add the aggregate slowly.

Mix for a further 1-2 minutes until the aggregate has fully combined and there are no lumps. The mixed unit should be applied immediately.

Resuflor SL F should be worked with a trowel or float to achieve an even smooth finish. This is best achieved by the application of smooth even pressure with the compound poured over the correct coverage rate after fixing the stop ends to control the flow of the material.

Then roll the area with a spiked roller to achieve an even smooth surface and remove entrapped air. Do not re-roll the area later than 15-20 mins. The surface should be protected from temperatures of less than 10°C and moisture in the early stages of cure.

This could adversely affect the flow, levelling and surface finish of Resuflor SL F.