We no longer stock this product, but can recommend Tor Elastaseal Z Fibretex as a great alternative.

We no longer stock this product, but can recommend Tor Elastaseal Z Fibretex as a great alternative.

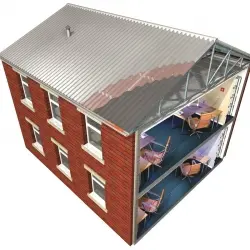

Tor Raincoat Fibretex (RC301) is a single pack, high build coating, based on a special modified acrylic/urethane resin system, containing inert pigments extenders and flame retardant agents, and reinforced with inert fibres for the waterproofing of sound solid sheeted pitched roofs (eg. asbestos/fibre, cement, factory coated profiled metal etc).

Preparation

The roof surface does not need to be completely dry, but care should be taken to ensure surfaces/substrates are adequately prepared and visibly dry. Identify any leaks. Remove any existing unsound remedial repairs, weak or loose material. Thoroughly scrub surfaces to be treated with a stiff bristle brush to remove dust, grime, loose chippings, etc and wash down to ensure proper cleaning. Moss, lichen, fungal growth, etc should be treated with Torkill W Fungicidal Wash (DM405). Porous or friable surfaces should be treated with Raincoat Stabilising Sealer (RC351). Solvent sensitive (eg. bituminous) surfaces should be treated with Raincoat Metallic Primer (RC352). Treat cleaned metal surfaces with Raincoat APA (RC353).

Ensure any gaps, splits etc are properly rectified, and if necessary stabilised with bridging/bond break tapes and Elastamat glass fibre mat reinforcements in conjunction with suitable embedment coats (e.g. Elastaseal or Torprufe CRC as appropriate).

Application

Brush and short/medium pile roller. Touch-in/stripe coat any minor cracks, lap joints, minor gaps etc. before applying main coat. Significant gaps/movement areas are likely to require additional treatment.

Limitations

Question: Does this paint need a primer on 1st or is this a primer/topcoat classed as a 1coat.. Its going on a cement compound garage roof and not asbestos | |

Answer from Rawlins’ Technical Team: Preparation The roof surface does not need to be completely dry, but care should be taken to ensure surfaces/substrates are adequately prepared and visibly dry. Identify any leaks. Remove any existing unsound remedial repairs, weak or loose material. Thoroughly scrub surfaces to be treated with a stiff bristle brush to remove dust, grime, loose chippings, etc and wash down to ensure proper cleaning. Moss, lichen, fungal growth, etc should be treated with Torkill W Fungicidal Wash (DM405). Porous or friable surfaces should be treated with Raincoat Stabilising Sealer (RC351). Solvent sensitive (eg. bituminous) surfaces should be treated with Raincoat Metallic Primer (RC352). Treat cleaned metal surfaces with Raincoat APA (RC353). Ensure any gaps, splits etc are properly rectified, and if necessary stabilised with bridging/bond break tapes and Elastamat glass fibre mat reinforcements in conjunction with suitable embedment coats (e.g. Elastaseal or Torprufe CRC as appropriate). | |

Question: Hi, Can this paint be applied by an electric paint sprayer? Thanks, Brigitta | |

Answer from Rawlins’ Technical Team: No, this product is for brush/roller application only. | |

Tor Raincoat Fibretex is only available with the shipping and delivery timescales listed below - please do not contact our Customer Support Team with enquiries about alternative or earlier shipping and delivery times.

Saturdays and Sundays, as well as Bank Holidays, are not classed as working days.

Orders placed after the cut-off for this product will not be processed for earliest dispatch until 9am the next working day.

All delivery costs below are excluding VAT