Chemical and acid resistant paints and coatings are designed to offer a lot more protection than standard coatings, which generally protect surfaces from day-to-day contact with hydraulic fluids, petrol, oil, and grease. The coatings available here are for high-end requirements:

- Buried metal and concrete structures

- Bund walls

- Cladding

- Railings

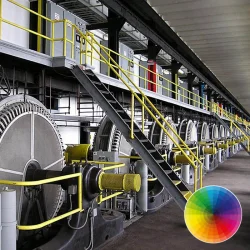

- Machinery and processing equipment

- Flue gas ducts

- Funnels

- Cooling towers

- Nuclear facilities

- Traffic and industrial fumes

- Liquid spillages

- Excellent flexibility

- Improved resistance against chemical attacks to a surface or substrate from long-periods of storage and transportation – typically from two-component coatings, like epoxy, polyurethane, methacrylate, and vinyl ester resins

- Corrosive petrol, diesel, acids, alkalis and solvents in industrial processing facilities where minimal surface cleaning is attainable

- Enhanced surface lubrication is required

- Improved component life from durable topcoats

- Surface heat and low-temperature handling capabilities

- Storage of high temperature chemicals

- Extreme protection in high humidity areas where high rates of salt water corrosion may be typical

- Improved resistance to anti-galling lubricants

- Protects marine environment surfaces from

- Salt spray

- Excessive moisture

- Oxidation and rust

- Other environmental chemicals

- Resilience against chemical compounds and corrosive materials

- Improved colour retention

- Extended surface and substrate lifespan

- High-gloss finishes

- Cost-effective long-term coating solutions for flooring in heavy machinery plants

- Abrasion resistance

- Thin film coating requirements that offer extended protection to the underlying surface or substrate

- And more

The chemical resistance of a coating will depend on a variety of criteria, including:

- The type of chemical

- Its concentration

- Temperature – environment and substance

- Level of exposure – full/partial, occasional contact

- Length of time exposed to the chemical

- The full paint system specifications

- Has there been any maintenance or repair work conducted?

- Interior or exterior location

- Substrate type

- Submerged, underground / under-soil location

- Will the surface be subject to abrasion and vehicular use?

- Cleaning regimes

- Humidity

- Required lifespan

- Substrate or surface preparation

- Stain resistance

- Weather protection characteristics

- How porous is the substrate?

- Surface exposure rate

- Walls

- Floors

- Ceilings

Chemically Resistant Epoxy Coatings

Please refer to product datasheets always, as scenarios given are not reflective of all products.

Epoxy coatings provide outstanding protection against caustic fluids, fuels including oil and petrol, fatty acids, salt or sugar solutions in food processing or pharmaceutical facilities, chemical cleaning and related cleaning detergents or product spillage.

Environments and surfaces specialist epoxy coatings may be used in include swimming pools, large floor areas, indoor car parks, garage floors, warehouse floors, workshops, showrooms, etc.

An aesthetical feature of epoxy paints is that they can produce a long-lasting super gloss or wet look. This may be preferred in environments where a facility is open to inspection, lectures, tours and showcase demonstrations.

In aggressive and extreme environments, a two component epoxy coating, like that found within International's Intergard 410, delivers as an anti-corrosive barrier for high-build sites and on external tanks. As with many Rawlins Paints' products, it comes available in a wide range of colours (see here for more detail).

Our help and advice promise

If you need any advice or guidance with your chemical resistant paint project, call our Technical Team to discuss what product(s) will be best for you. Site visits can be carried out for larger projects so a full specification can be produced in writing, which will be tailored to meet the projects requirements. Data sheets and advice are always freely available to help you with your project.